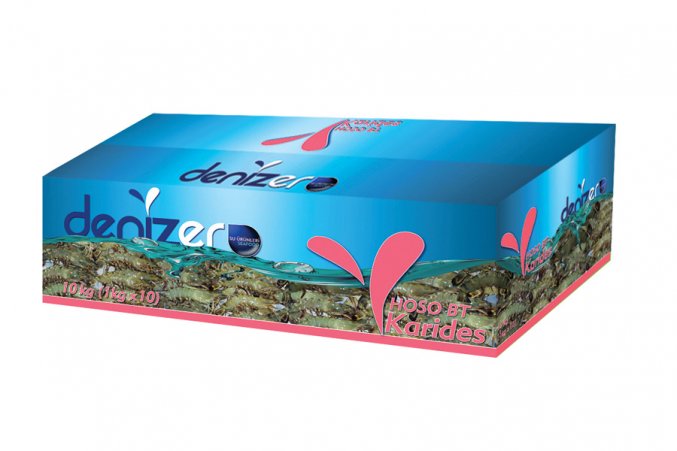

Hoso BT Prawn

Among the tiger shrimp species, also it is a prawn, it is most commercial type and farmed in many countries around the world. It is found naturally in India-West Pacific. Based on its high tolerance, it is suitable for aquaculture.

It is a very delicious shrimp type and present to consume as meat with tail on, butterfly, meat tail off, buttered and breaded.

Product Description

| Product name | Denizer Deep Frozen HOSO BT Prawn 10 kg |

| Latin name | Penaeus monodon |

|

External barcode |

4-6: 8680539204029 6-8: 8680539204043 8-12: 8680539204067 13-15: 8680539204081 16-20: 8680539204104 21-30: 8680539204128 |

|

Internal barcode |

4-6: 8680539204036 6-8: 8680539204050 8-12: 8680539204074 13-15: 8680539204098 16-20: 8680539204111 21-30: 8680539204135 |

| Size | 4-6, 6-8, 8-12, 13-15, 16-20, 21-30 / Size before glazing √ / Size after glazing |

|

Product description |

After harvesting, BT prawn is graded, freezed individual and placed on plates with some water (34%). After freezing, the product is packed in 1 kg inner carton. |

| Freezing type | Semi IQF (Semi Individual Quick Freezer) |

| Packing type | 10 x 1 kg inner box |

| Ingredients | HOSO White prawn (80%), water (20%) |

| Production type | Farmed / Catch √ (FAO : 51 ) / Value added |

| Origin | Indonesia |

|

Units per package |

4-6: 4-6 pcs/kg 6-8: 6-8 pcs/kg 8-12: 8-12 pcs/kg 13-15: 13-15 pcs/kg 16-20: 16-20 pcs/kg 21-30: 21-30 pcs/kg |

| Glazing rate | 20% |

| Product type | HOSO prawn |

| Broken pieces | Max 1 piece / 1 kg |

| Appearence | Darker bands, specific appearence |

| Smell | Specific smell |

| Taste | Specific, not bitter or sour, natural taste |

| Texture | Strict, not dry |

| Average weight | 4-6: 170 g / 6-8: 125 g / 8-12: 84 g / 13-15: 77 g / 16-20: 50 g / 21-30: 35 g |

| Shelf life | After production date, first 24 months |

| Additives | No chemical |

| Outer package | Min 4 colored printing microwave corrugated cardboard box (PAP) (26x53,5x20 cm) |

| Inner package | Min 4 colored printing inner box |

|

Packing criteria |

The total migration value of components of plastic substances and materials to foodstuff, per square decimeter surface area of substance or material can not be more than 10 mgs. This value is defined as the limit of total migration of plastic substance and materials (mg/dm2). |

|

Storage conditions |

Should transport and storage at min -18°C. Transportation should be without contamination and complete with no break of cold chain. |

Nutrition facts

| Energy (kcal/100 g) | 100 |

| Fat (g/100 g) | 1,5 |

| Protein (g/100 g) | 15 |

| Cholesterol (mg/100g) | 145 |

| Na (mg/100g) | 290 |

| Carbonhydrate (mg/100g) | 0 |

| Vit A (%/100 g) | 0 |

| Vit C (%/100 g) | 4 |

| Ca (%/100 g) | 50 |

| Fe (%/100 g) | 11 |

| Omega 3 (g/100 g) | 5 |

Chemical Parameters

| Hg (mg/kg) | 0,5 |

| Cd (mg/kg) | 1 |

| Pb (mg/kg wet weight) | 1 |

| Total max dioxins (pg/g wet weight) |

3,5 |

| Total max dioxins and dioxin like PCBs (pg/g wet weight) |

6,5 |

| Total PCB28, PCB52, PCB101, PCB138, PCB153 and PCB180 (ng/g wet weight) |

75 |

Microbiological Parameters

| Histamin (mg/kg) | 100-200 |

| Salmonella spp(g-ml) | - |

| Listeria monocytogenes (g-ml) | - |

Legal Criteria

| GKGM Regulation on water intended for human consumption |

| GKGM Regulation on microbiological criteria |

| GKGM Regulation on contaminants |

| GKGM Regulation on labelling |

| GKGM Regulation on packaging waste control |

| GKGM Statement of plastic materials in contact with foodstuffs |

| Turkish Food Codex Regulation |

Determination of Net Weight

| Apparatus |

| Container - Wire mesh basket large enough to hold contents of one package and with openings small enough to retain all pieces. Expanded metal test-tube basket or equivalent, fully lined with standard 16 mesh per linear inch (2.54 cm) insect screen is satisfactory. |

| Balance - Sensitive to 0.25 g or 0.01 oz. |

| Transfer product to circular No. 8 sieve, 20 cm (8”) diameter for packages #0.9 kg (2 lb) and 30 cm (12”) for packages >0.9 kg (2 lb). |

| Sieves - U.S. No. 8, 20 cm (8”) and 30 cm (12”). |

| Determination |

| Place contents of individual package in wire mesh basket and immerse in 15 L (4-gal.) container of fresh water at 26 ± 3ºC (80 ± 5ºF) so that top of basket extends above water level. Introduce water of same temperature at bottom of container at flow rate of 4-11 L (1-3 gal.)/min. As soon as product thaws, as determined by loss of rigidity, transfer all material to 30 cm (12”) (for packages 450 g [1 lb.]), or 20 cm (8”) (for packages ≤450 g [1 lb.]) No. 8 sieve, distributing evenly. Without shifting material on sieve, incline sieve to ca 30º from horizontal to facilitate drainage. Two minutes from time placed on sieved, transfer product to previously weighed pan, and weigh. Weight so found minus weight of pan is drained weight of product. |

| *Acc to AOAC 967.13 Drained weight of frozen crabmeat and shrimp |

Spawning

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec |

| X | X | X | X | X | X | X | X | X | X | X | X |